Fax 1-800-572-0839 21

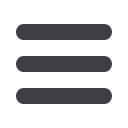

END MILL HOLDERS

Collis

A B C

Number

Description

Bore Proj. Dia. Wrench

74270

CV40MC .750 X 3.70 .75 3.70 2.37 64705

74271

CV40MC 1.250 X 4.52 1.25 4.52 2.94 64706

74273

CV50MC 1.250 X 4.45 1.25 4.45 2.94 64706

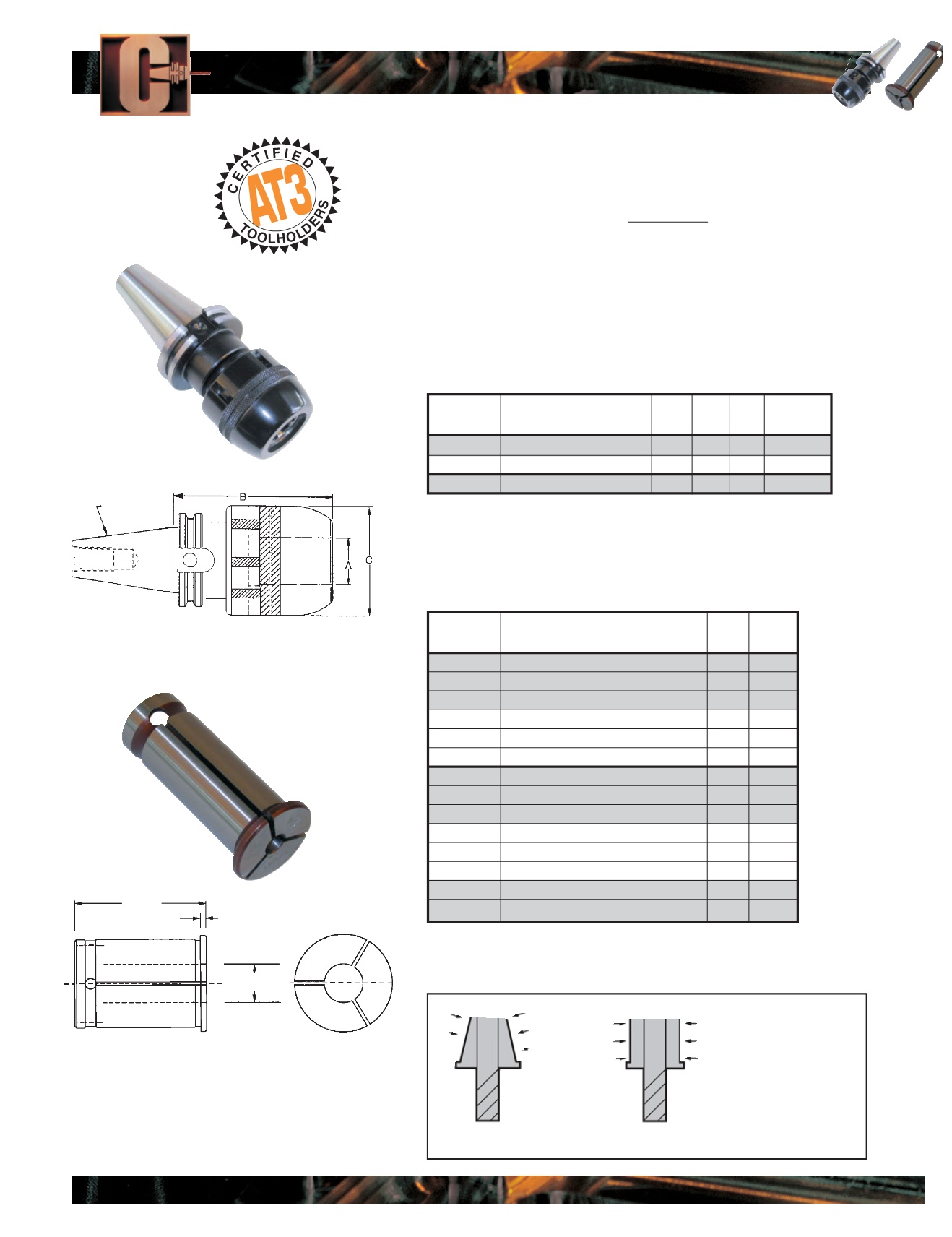

Collis

A B

Number

Description

Bore O.A.L.

74285

.750 MC COLLET 1/4"

.250 2.06

74286

.750 MC COLLET 5/16"

.312 2.06

74287

.750 MC COLLET 3/8"

.375 2.06

74289

.750 MC COLLET 1/2"

.500 2.06

74284

.750 MC COLLET 9/16"

.562 2.06

74290

.750 MC COLLET 5/8"

.625 2.06

74291

1.25 MC COLLET 1/4"

.250 2.88

74292

1.25 MC COLLET 5/16"

.312 2.88

74293

1.25 MC COLLET 3/8"

.375 2.88

74295

1.25 MC COLLET 1/2"

.500 2.88

74296

1.25 MC COLLET 5/8"

.625 2.88

74297

1.25 MC COLLET 3/4"

.750 2.88

74298

1.25 MC COLLET 7/8"

.875 2.88

74299

1.25 MC COLLET 1"

1.00 2.88

Milling Chuck Holders

Milling Chuck Collets

Collets

Tapered Collets

Straight Collets

Collet moves

Collet stays. Depth

when tightened.

adjustment is not altered.

With Straight

Collets, an end

mill is held

strongly and

evenly by the

entire length of

its shank.

•

Extreme rigidity.

•

Axial accuracy: Concentricity < .0002"

_

•

Straight bushings will grip the end mill evenly across the end mill shank.

This provides a gripping force twenty times greater than a standard

tapered collet.

•

Flats and end mill shank depressions will not distort the milling chuck

bore.

•

Tightening torque of 22 FT/LB’s is minimal for a tremendous gripping

force as compared to a tapered collet chuck.

•

The collapse range is .0015" below nominal.

•

Holders has coolant thru capabilities

The only AT3 certified

toolholder available.

B

A

.105

•

Retention knob separate item – see page 121.

CV SHANK